Introduction to Shoe Industry ERP System (Shoe Industry ERP System)

Shoe Enterprise Resource Planning (ERP) is the abbreviation for Enterprise Resource Planning (ERP) in the footwear industry. It refers to a management platform that is built on the basis of information technology, integrates information technology and advanced management ideas, and provides decision-making tools for enterprise employees and decision-makers with a systematic management approach. Shoe ERP is a new generation of integrated management information system developed from MRP (Material Requirements Planning), which expands the functional boundaries of MRP and focuses on efficient management of the enterprise's supply chain. Function introduction: 1. After implementing the Universal Footwear ERP management software for material coding management, the material coding method can be freely defined, and the material coding can be scientifically classified, achieving the nature of material coding. The system can automatically generate material codes and names, greatly reducing the workload of material coding and improving work efficiency.

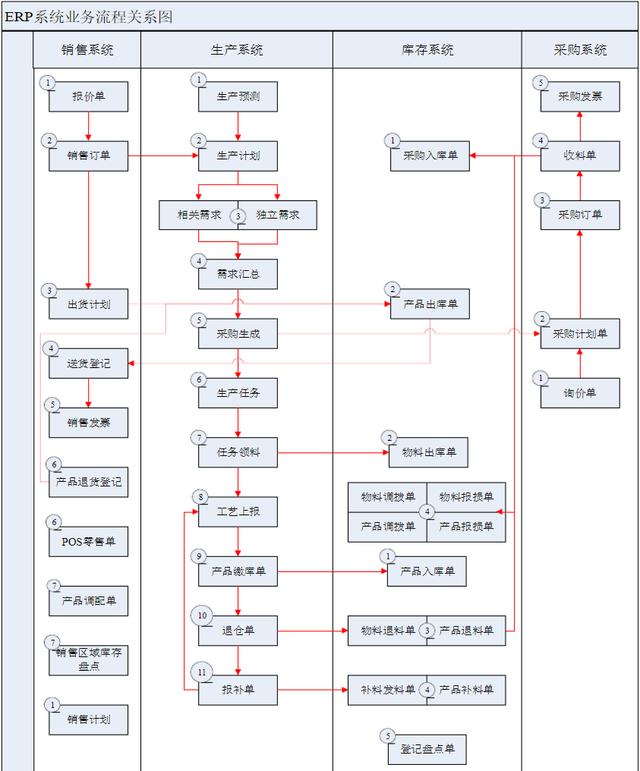

2. Development management enables the management of BOM for different development stages of products, automatically conducting material cost budget analysis and customer quotation operations on BOM data for different development stages, greatly reducing quotation workload and providing accurate data for product mass production and procurement. 3. Through the analysis of product production capacity and labor standard cost, the process flow can accurately calculate the standard production capacity and standard working hours of the product, providing a scientific basis for production planning and performance evaluation. 4. Logistics management realizes the automatic calculation of the required material quantity according to the demand plan, generates accurate material procurement plans, reduces waiting and obsolete materials, and reduces inventory funds. In terms of material requisition for production, the system strictly controls the quantity of order materials within the standard usage, thereby controlling the material cost of the order and ensuring production profits. Eliminated the situation of receiving too many or wrong materials in the past. 5. Production management can automatically schedule production progress based on business order data, product process routes, and production load conditions of work centers. By inputting production and inventory data into the computer, it is possible to timely understand the production dynamics of orders, identify production bottlenecks in a timely manner, and enable production supervisors to have a clear understanding of production information. It can automatically generate various production statistical analysis reports, production daily reports, production progress tracking reports, etc., greatly reducing manual workload, providing work efficiency, and saving costs.

6. The unit price of the asset management process is controlled within the standard cost, and the number of reported items is controlled within the order quantity. Strict permission control has eliminated errors, omissions, undercounting, and embezzlement, greatly improving the production enthusiasm of employees. 7. The human resources system combines personnel, attendance, salary, and salary organically, achieving complete data sharing. The salary system can automatically and flexibly define salary items and calculation formulas according to user needs, providing flexibility and accuracy in salary calculation, enabling monthly salary reports to be submitted to company supervisors accurately and timely.

8. The uncertainty of human factors in barcode management leads to low labor efficiency and serious waste of human resources. With the increase of inventory variety and quantity, as well as the sharp increase in inbound and outbound frequency, the traditional warehouse operation mode seriously affects the normal operational efficiency. All finished products are managed using barcode, which solves the automation of data input for warehouse operators and achieves accurate data transmission, ensuring warehouse operation efficiency. The barcode system will solve the current problem of manual counting in warehouse inventory, improve inventory efficiency and accuracy, accelerate business input speed and reduce data error rate, greatly improving the inventory quantity and data accuracy of finished products. By using the association management of business documents, we can reduce duplicate entry of business documents and effectively improve the work efficiency of business departments. 9. Financial management is a relatively standard system, and the relevant reports are set in accordance with relevant national laws, regulations, and standard formats. In the planning and design of this section, we strive to mobilize system resources as much as possible, and a large amount of data calls and report generation are all automatically completed by the system, minimizing the amount of data and time input by financial personnel. In terms of operation, we strive for simplicity and practicality, allowing operators more time to verify the original data, ensuring the accuracy and consistency of the data. In addition, we have also developed corresponding reports according to the needs of the factory, Meet the needs of the enterprise as much as possible.